Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() September 11, 2023

September 11, 2023

Polyvinyl Alcohol PVA is made from vinyl acetate (VAc) through polymerization and alcoholysis. PVA is a typical water-soluble polymer with a glass transition temperature of 60-85 ℃ and a melting point of 200 ℃. Molecules contain a large number of hydroxyl groups, which are easily cross-linked through hydrogen bonds to form a large molecular network structure. Therefore, PVA materials have excellent water solubility, film formation, adhesion, reactivity, and biological affinity, as well as good biocompatibility and certain biodegradability, which can be degraded under the action of specific PVA degrading enzymes. PVA has a regular structure and strong hydrogen bonds within its molecules. Its high crystallinity makes its melting temperature higher than the decomposition temperature, making it difficult to melt and process.

1、 Global and domestic total production capacity

The global production of polyvinyl alcohol (PVA) is mainly concentrated in a few countries and regions such as China, Japan, and the United States, with a total production capacity of approximately 1.85 million tons. In 2020, the actual production was around 1.35 million tons, with the Asia Pacific region being the main production region, accounting for over 85% of the world's total production.

According to statistics, in 2020, China's total production capacity of polyvinyl alcohol was 996000 tons (excluding Taiwan), with an actual output of about 810000 tons, making it the world's largest producer of polyvinyl alcohol.

2、 Production capacity and process route statistics of PVA company

The representative enterprises of polyvinyl alcohol in the world, excluding China, mainly include Japan's Kolli Co., Ltd., Japan's Shuishui Chemical Industry Co., Ltd., Japan's Synthetic Chemical Industry Co., Ltd., Japan's Unijica (JVP), and the United States' DuPont Company. In 2020, the global total production capacity was about 1.85 million tons, with the majority using the ethylene method.

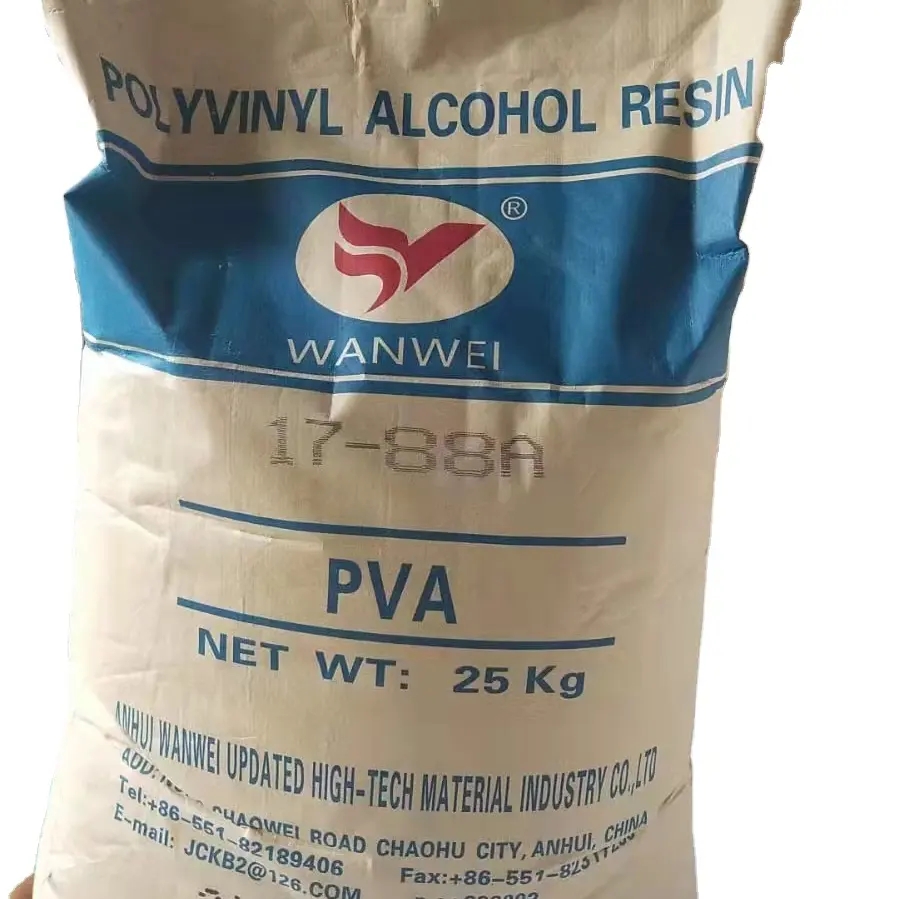

Wanwei High tech is a leader in the PVA industry

The production capacity of polyvinyl alcohol Resin enterprises in China is mainly distributed in seven enterprises, including Anhui Wanwei High tech Materials Co., Ltd., Sinopec Chongqing Chuanwei Chemical Co., Ltd., Ningxia Dadi Recycling Development Co., Ltd., Inner Mongolia Shuangxin Environmental Protection Materials Co., Ltd. In 2020, the total production capacity was 996000 tons, and more than 60% of PVA production units were produced using the calcium carbide acetylene method.

Anhui Wanwei High tech Materials Co., Ltd. is a national high-tech enterprise under the Wanwei Group, with strong technological innovation and independent research and development capabilities. It is a leading enterprise in China's polyvinyl alcohol industry. According to statistics, the overall revenue of Anhui Weixin High tech from 2012 to 2020 showed an increasing trend. As of the first half of 2021, the revenue was 3.753 billion yuan, a year-on-year increase of 39.38%. Among them, the revenue from polyvinyl alcohol business was 1.106 billion yuan, a year-on-year increase of 9.53%, accounting for 29.47% of the total revenue. As of 2020, Wanwei High tech's polyvinyl alcohol production was 265800 tons, a year-on-year increase of 11.96%, and sales were 228000 tons, a year-on-year increase of 4.18%.

It is understood that there are currently 17 enterprises in China that produce polyvinyl alcohol. Among them, the PVA production enterprises under Wanwei Group include Guangxi Guangwei and Inner Mongolia Mengwei in addition to Anhui Wanwei High tech Materials Co., Ltd. Sinopec Group has three subsidiaries: Shanghai Petrochemical, Beijing Organic Chemical Plant, and Sichuan Chuanwei. Sinopec Group has two subsidiaries: Hunan Xiangwei and Guizhou Crystal, The subsidiary of Shanghai Baowang Group is Jiangxi Jiangwei.

3、 PVA application field

In the global consumption structure of polyvinyl alcohol, polymerization additives, polyvinyl butyral (PVB), textile pulp, and adhesives are the main downstream consumer markets for polyvinyl alcohol. In China, the downstream consumer markets of polyvinyl alcohol mainly include polymerization additives, fabric slurries, adhesives, etc.

Polymerization aids

Polyvinyl alcohol is commonly used as a protective adhesive in suspension polymerization to improve the dispersion stability of suspension polymerization systems. Polyvinyl alcohol is also widely used as a stabilizer in the lotion polymerization process to improve the stability of the lotion polymerization system and the stability of the polymer lotion.

Textile size

The sizing material made of polyvinyl alcohol does not decay or deteriorate, and has good adhesion to cotton, linen, polyester, Polypropylene, and artificial fibers. The sizing film is smooth and strong, which can increase the strength of the yarn, reduce breakage, and save dosage. It is easy to desize. Therefore, it is widely used in the sizing of chemical fiber long and short fibers, viscose fibers, and textile post-processing.

Adhesive

Adhesive made from polyvinyl alcohol has the characteristics of non spoilage and stable quality, and can replace starch, water glass, or be used in combination with it. Due to the strong adhesion of polyvinyl alcohol aqueous solution to paper, good film-forming ability, and strong skin flap, it can replace expensive and easily perishable casein to make pigment adhesives. Coated paper has good whiteness and glossiness, is not easy to curl, and has low cost. Therefore, it has a wide range of applications in advanced paper such as art paper and craft paper. And due to the unique water-soluble advantages of polyvinyl alcohol, it can be used to make a re wetting adhesive (commonly known as "non drying adhesive") for labels, stamps, wallpaper, and packaging tapes.

Vinylon Fiber

The good drawing performance has established the position of polyvinyl alcohol as a raw material for polyvinyl alcohol fibers. Vinylon fibers made from polyvinyl alcohol have advantages such as white color, high strength, good moisture absorption, wear resistance, sun resistance, and corrosion resistance. They can be blended or pure spun with cotton, wool, and viscose fibers, and are used for industrial purposes such as clothing and tarpaulins, cord cords, fish nets, and ropes. They are also good substitutes for asbestos. In recent years, developed countries such as Europe and America have adopted high-strength and high modulus PVA to replace asbestos, and have achieved good results in the manufacturing of asbestos free cement boards.

Paper industry

The paper surface sizing agent made of polyvinyl alcohol can increase the surface strength and internal tensile strength, elongation, rupture resistance, folding resistance, and wear resistance of the paper, increase the gloss and smoothness of the paper, improve the water resistance, oil resistance, and organic solvent resistance of the paper, and improve the printing and brushing adaptability. It can also be used as a bonding agent for paper tubes or paperboard, as well as for the re wetting of stamp adhesive, as well as for the bonding agent for pigment coating engineering and the internal gluing of paper products.

Construction field

The application of high-strength PVA fiber in building materials has become increasingly widespread, and it is used for strengthening concrete in buildings, such as cement slabs, sewers, the ground of front observation platforms, parking lots, etc; It can also be used as an ideal substitute for cement and fiberglass, as well as for fiber reinforcement in interior decoration. PVA is also being increasingly widely used in interior wall coatings and adhesives.

Polyvinyl alcohol film

PVA films can be divided into room temperature dissolution films, medium temperature dissolution films, and high temperature dissolution films, which are applied in different fields. PVA film currently has a small market share in the downstream of PVA, but its application has become increasingly widespread in recent years. Modifying PVA to improve the water resistance and degradation properties of PVA materials can greatly expand the application range of PVA film. For example, water-soluble PVA film has been widely used for packaging various products in Europe, America, and Japan, and many large companies such as Bayer are also using it.

The above is the Understanding PVA in one article, market overview of PVA industry we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.